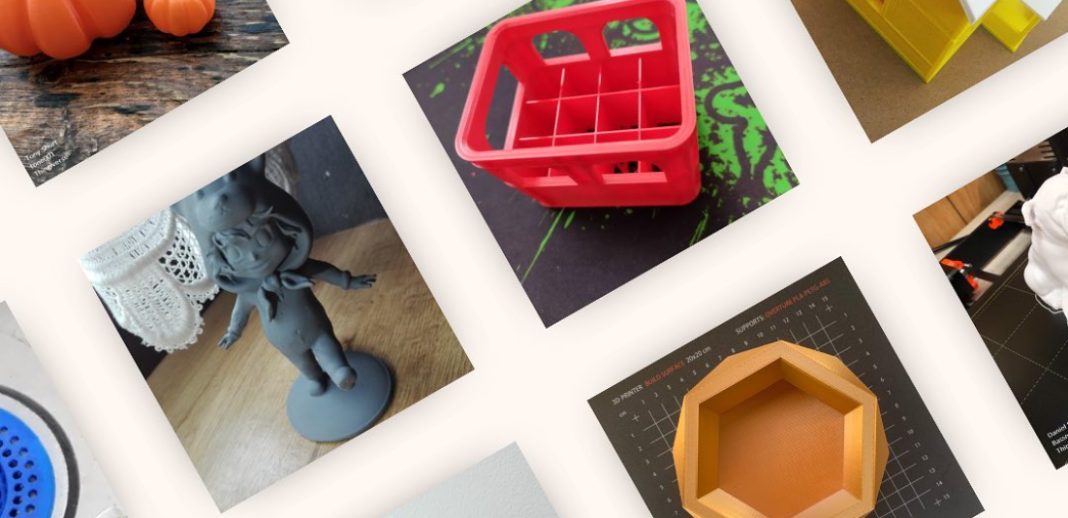

3D printing, also known as additive manufacturing, is a revolutionary technology that has significantly impacted various industries, especially in the field of prototyping. Here are some of the key benefits of using 3D printing for prototypes:

- Rapid prototyping: 3D printing allows for the quick and cost-effective production of prototypes. Traditional manufacturing methods often require expensive tooling and longer lead times, whereas 3D printing can create a prototype in a matter of hours or days, depending on the complexity.

- Design flexibility: Design iterations can be easily implemented in the digital model and printed on the spot, enabling designers to make adjustments and improvements rapidly. This flexibility reduces the time required to iterate on the design and helps in refining the final product.

- Cost-effective: In the past, creating prototypes involved significant upfront costs for tooling and molds. With 3D printing, there is no need for expensive tooling, making it more affordable, especially for small production runs and custom designs.

- Customization: 3D printing enables the creation of highly customized prototypes to suit specific requirements. It is particularly useful in fields like medical devices, where personalized products are necessary.

- Complex geometries: 3D printing allows for the fabrication of intricate and complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods. This opens up new possibilities for innovative designs and unique products.

- Reduced waste: Traditional manufacturing processes often result in a significant amount of material waste. In contrast, 3D printing is an additive process that only uses the necessary material, minimizing waste and environmental impact.

- Time-to-market: Faster prototyping means reduced development cycles, leading to quicker time-to-market for new products. This advantage is crucial for staying ahead in competitive industries and meeting consumer demands.

- Testing and validation: 3D printed prototypes allow for real-world testing and validation of a design before investing in large-scale production. Identifying and addressing potential issues early on can save time and resources down the line.

- Iterative improvement: Since 3D printing allows for rapid and affordable prototyping, it encourages a culture of constant improvement. Engineers and designers can continuously iterate and refine their designs until they achieve the desired performance and functionality.

Overall, 3D printing has revolutionized the way prototypes are developed, providing numerous advantages that have accelerated product development, reduced costs, and fostered innovation across various industries.

We have a 3D printing farm where we can print your designs in PLA filament or other filaments depending on your needs and special requests. Just send us your STL file and we’ll send you a quote.

If you don’t have a STL file or don’t know where to start, try these sites: thingiverse.com, cults3d.com, myminifactory.com, printables.com, among others, where you can find thousand of models to choose from, just make sure to send us the .stl file for a quote.

We use the best FDM 3D printers in the market and high quality filament to deliver quality products.

Let’s 3D Print! We deliver!

T. +507.836.7132